Antistatic insoles are designed to work in conjunction with antistatic safety shoes, effectively directing human-generated static electricity to the ground, ensuring worker safety and preventing static-related accidents.

As a consumable part of safety shoes, the lifespan of antistatic insoles is generally shorter than that of the shoes, but their market demand is widespread, making them an essential component in the safety footwear supply chain.

Choosing the right antistatic insole can extend the life of safety shoes, reduce replacement costs, and improve work efficiency.

The main function of antistatic insoles is to direct the static electricity generated by the human body to the ground, effectively preventing static buildup and electrostatic discharge (ESD) from posing a potential threat to employee and equipment safety. As humans move, they carry static charges, which need to be safely directed through the insoles to the ground, eliminating static buildup and preventing harm to electronic equipment, components, and workers.

Antistatic insoles are typically made from conductive materials such as conductive fibers and carbon fibers. These materials have excellent conductivity and can quickly discharge static electricity to the ground when they come into contact with the floor, ensuring effective static dissipation.

The market for antistatic insoles is closely tied to the safety shoe industry. With the growth of manufacturing, logistics, electronics, and chemical industries, the demand for safety shoes—and by extension, antistatic insoles—continues to rise.

Electronics Industry

Chemical Industry

As multinational companies increase their demand for static protection, the Global market for Antistatic insoles grows.

Antistatic insoles are consumables with a short lifespan, but their demand remains stable, especially in high-intensity environments.C23

Full-foot conductive insoles for electronics and chemical industries; conductive thread insoles for office or light industrial use.

Choose insoles that provide comfort and durability based on work hours.

High-quality insoles reduce replacement frequency, lowering long-term procurement costs.

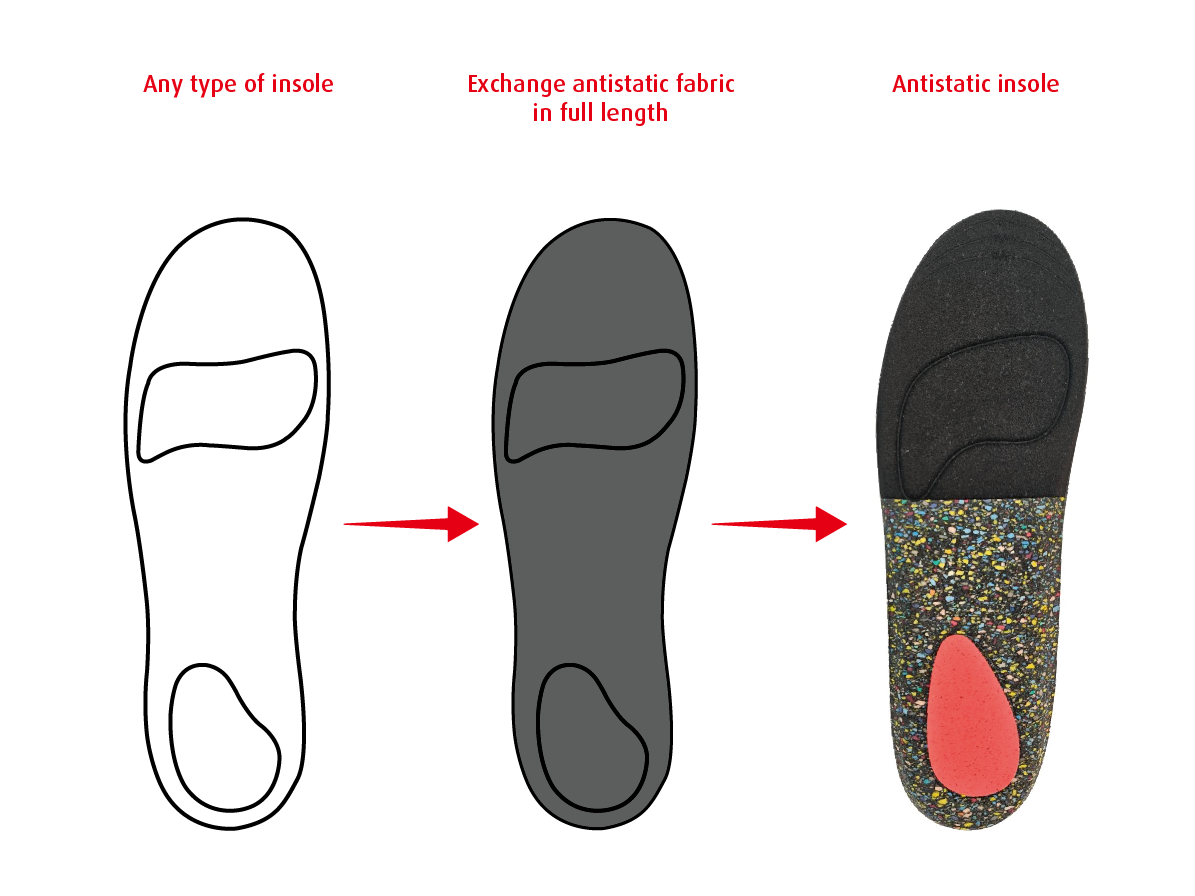

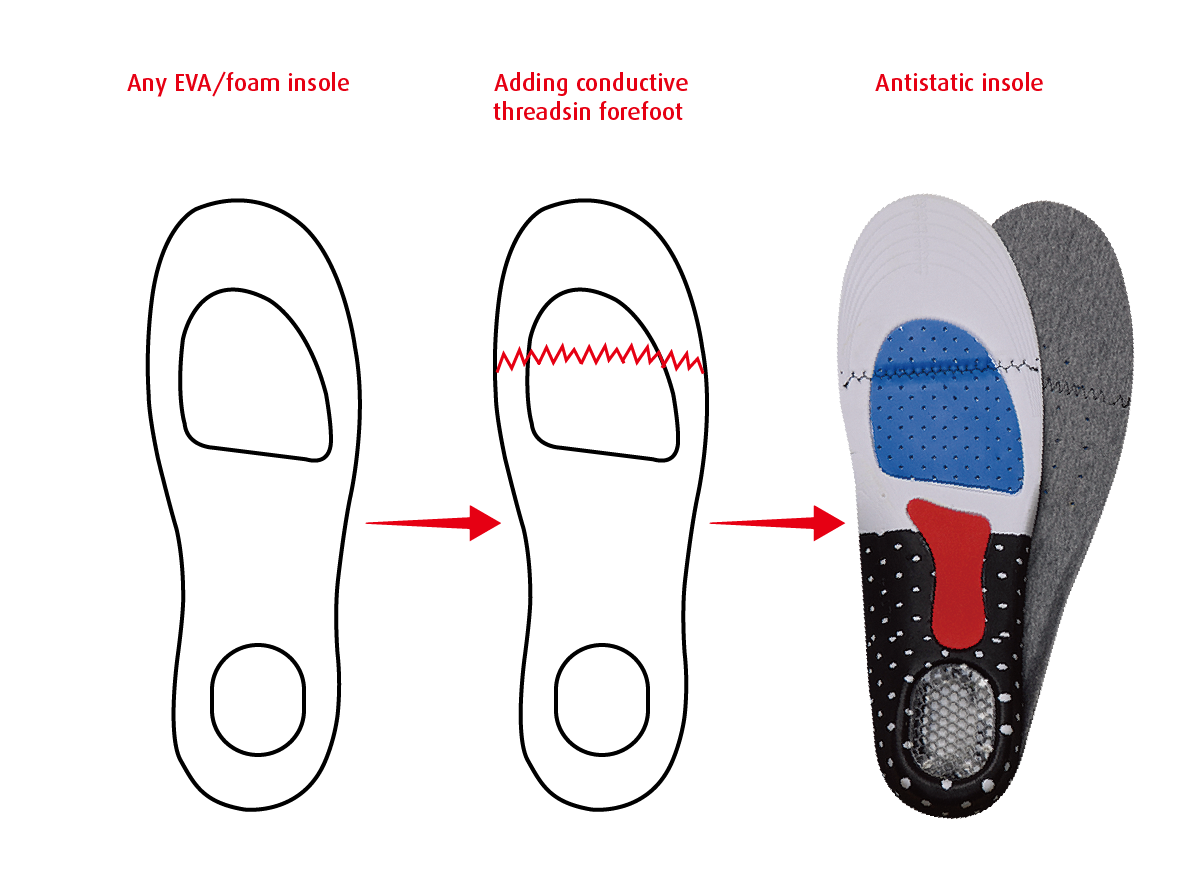

Antistatic insoles come in various styles and can be customized to meet the specific needs of different industries. The most common designs include full-foot conductive insoles and conductive thread insoles, both offering effective static protection through specially selected materials.

Made with black antistatic fabric on the front and black Antistatic Bollyu back fabric, ensuring the entire insole is conductive. This design is ideal for high-static protection industries such as electronics and chemicals. Any other insole style using these materials can achieve full-foot conductivity.

For environments with lower static protection requirements (such as regular office settings or light industries), antistatic insoles can be made by adding conductive threads to a standard insole material. While the conductive effect is relatively mild, it is sufficient to handle lower static risks in daily work environments, and this design is more cost-effective.

Regardless of the style selected, the static protection performance is guaranteed by the materials and processes used. Our customization services provide flexible solutions to meet specific business needs.

Choose from various insole styles, such as flat comfort insoles or corrective insoles. Different styles can incorporate different antistatic processes to ensure effective static protection.

Choose from various insole styles, such as flat comfort insoles or corrective insoles. Different styles can incorporate different antistatic processes to ensure effective static protection.

Regardless of the design, antistatic insoles should always be used in conjunction with antistatic safety shoes. The two components work together to ensure optimal conductivity, safely directing static electricity away and preventing sparks, equipment damage, or safety hazards to employees.

By choosing our antistatic insoles, you not only get superior static protection but also ensure full compliance with international safety standards, safeguarding both employees and equipment.

Our antistatic insoles are designed and tested according to several international standards, ensuring the highest level of static protection:

Antistatic shoes must have a resistance value between 100 kΩ and 100 MΩ, ensuring effective static dissipation and preventing safety hazards from excessively low resistance.

Resistance value should be between 100 kΩ and 1 GΩ, ensuring effective static release while keeping the wearer safe.

Antistatic footwear should have a resistance value between 1 MΩ and 100 MΩ, ensuring effective static protection.

Our antistatic insoles have a resistance value of 1 MΩ (10^6 Ω), fully complying with the above standards. They effectively dissipate static without compromising safety.

We use Resistance Meters to conduct thorough quality checks, ensuring each batch of insoles meets the required resistance range:

Static cannot be effectively released, leading to static accumulation and an increased risk of electrostatic discharge.

Approaches a conductor state, excessive static release could cause electric shock sensations or risk to the wearer.

Our insoles are within the 1 MΩ (10^6 Ω) resistance range, fully compliant with international standards, and offer reliable protection for employees and equipment.

Sample Confirmation, Production, Quality Inspection, and Delivery

At RUNTONG, we ensure a seamless order experience through a well-defined process. From initial inquiry to after-sales support, our team is dedicated to guiding you through each step with transparency and efficiency.

Fast Response

With strong production capabilities and efficient supply chain management, we can quickly respond to customer needs and ensure timely delivery.

Quality Assurance

All products undergo rigorous quality testing to ensure they do not damage the suede.y delivery.

Cargo Transport

6 with over 10 years of partnership, ensures stable and fast delivery, whether FOB or door-to-door.

Start with an in-depth consultation where we understand your market needs and product requirements. Our experts will then recommend customized solutions that align with your business objectives.

Send us your samples, and we’ll quickly create prototypes to match your needs. The process typically takes 5-15 days.

Upon your approval of the samples, we move forward with the order confirmation and deposit payment, preparing everything needed for production.

After production, we conduct a final inspection and prepare a detailed report for your review. Once approved, we arrange for prompt shipment within 2 days.

Receive your products with peace of mind, knowing that our after-sales team is always ready to assist with any post-delivery inquiries or support you may need.

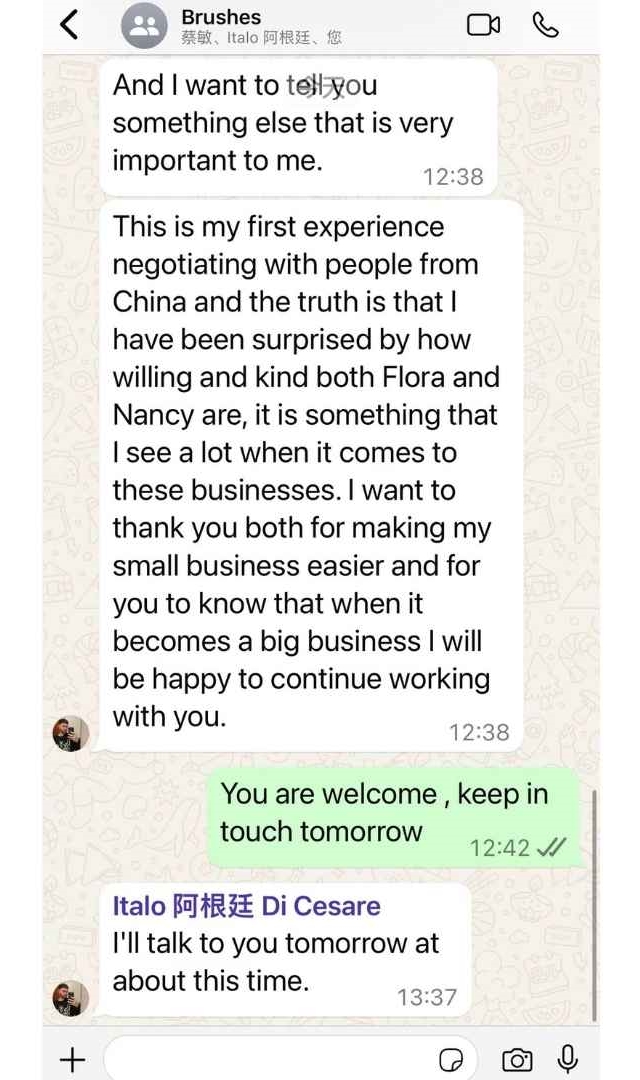

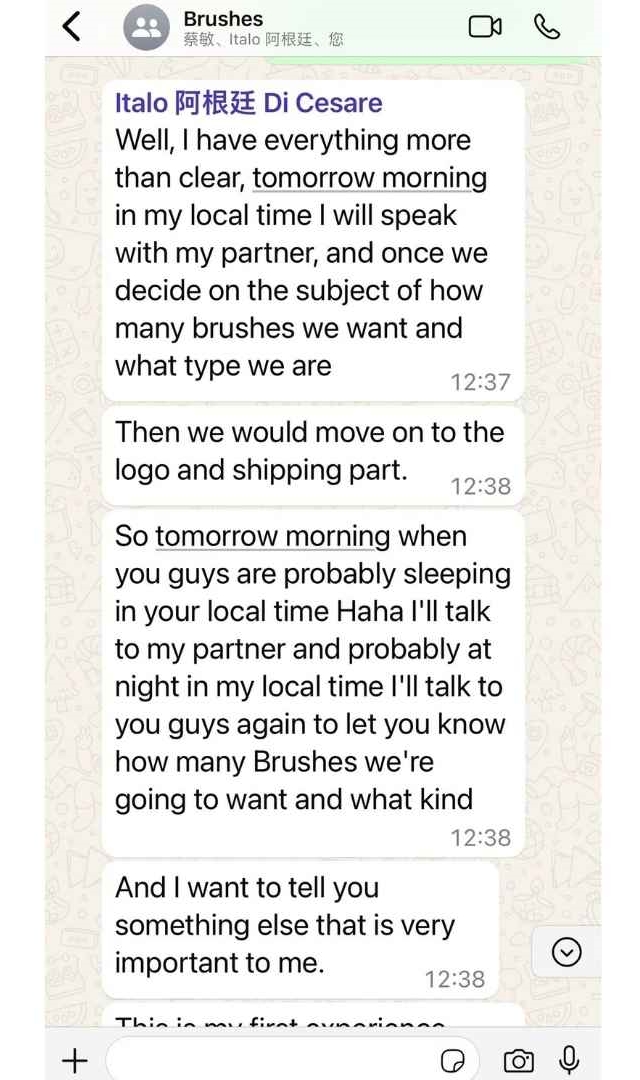

Our clients’ satisfaction speaks volumes about our dedication and expertise. We are proud to share some of their success stories, where they have expressed their appreciation for our services.

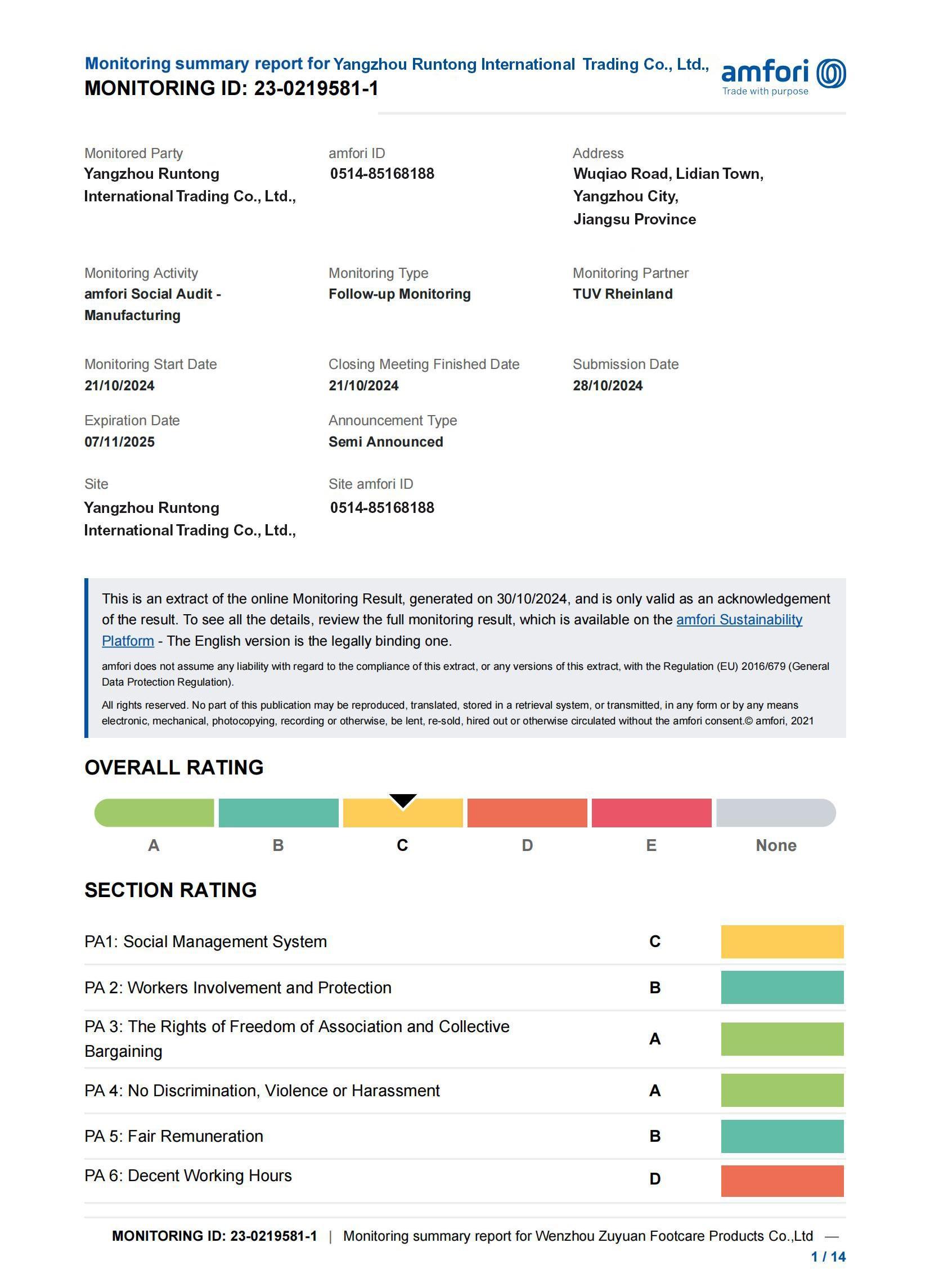

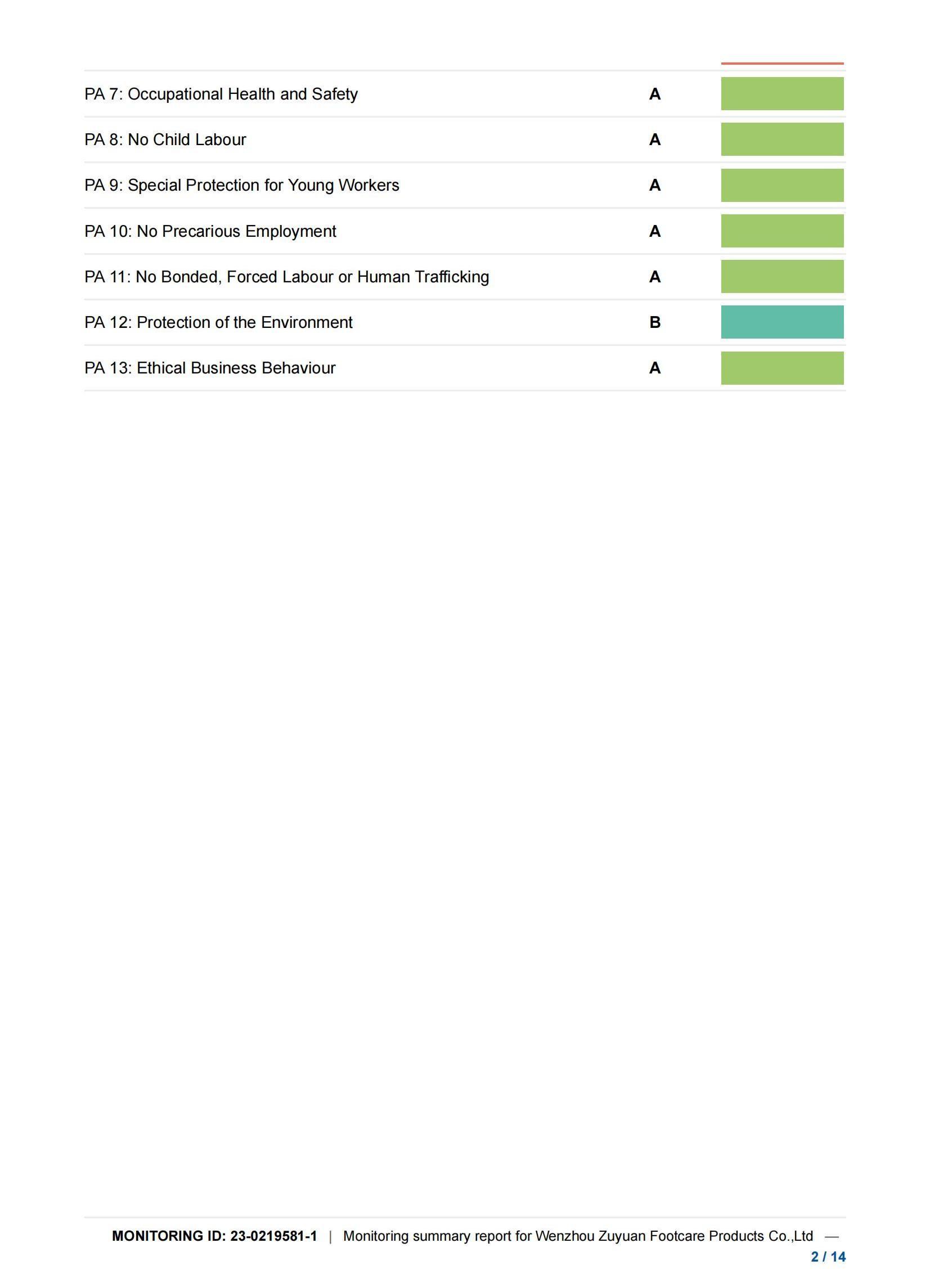

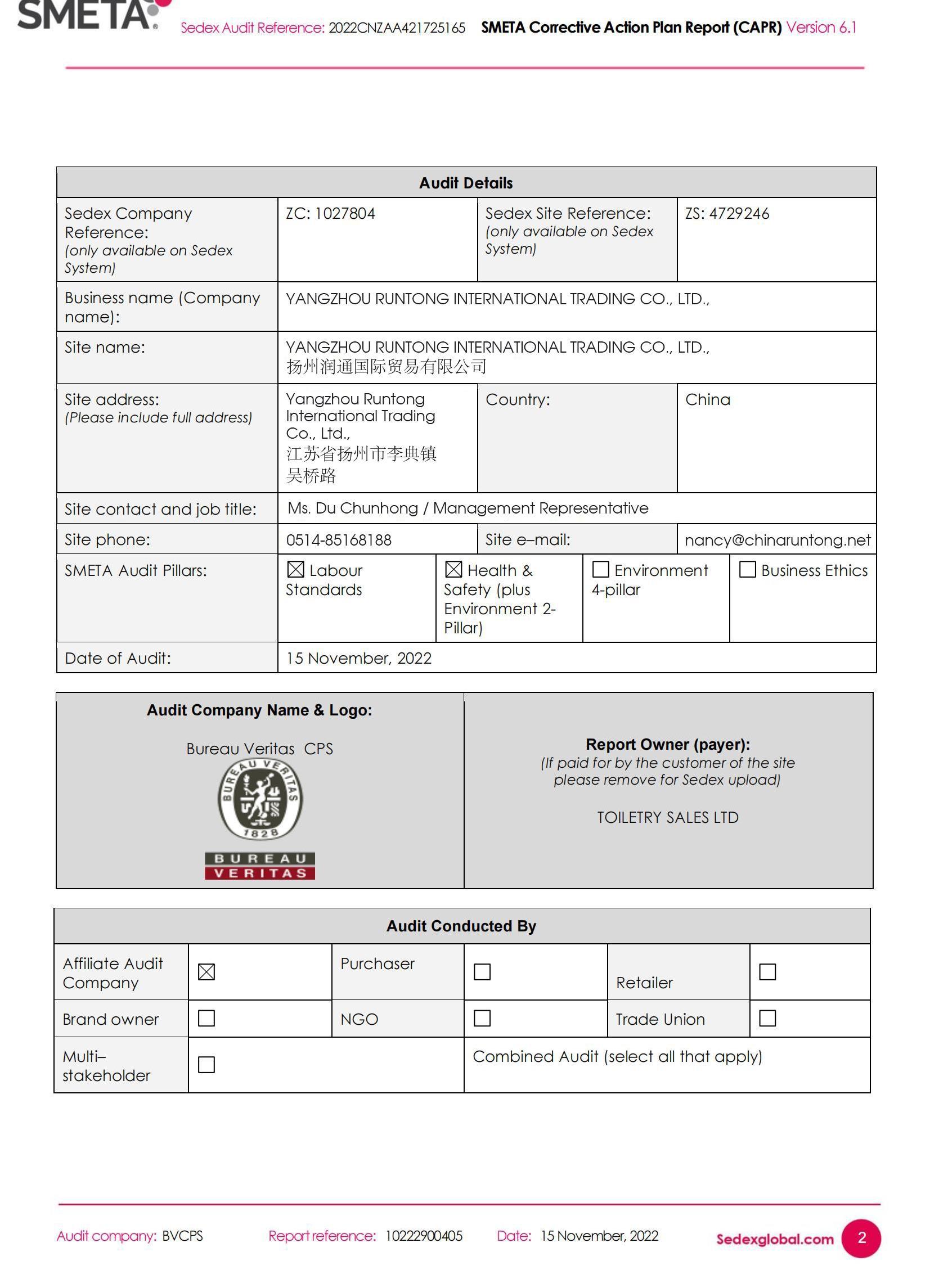

Our products are certified to meet international standards, including ISO 9001, FDA, BSCI, MSDS, SGS product testing, and CE certifications. We conduct rigorous quality control at every stage to guarantee that you receive products that meet your exact specifications.

Our factory has passed strict factory inspection certification, and we have been pursuing the use of environmentally friendly materials, and environmental friendliness is our pursuit. We have always paid attention to the safety of our products, complying with relevant safety standards and reducing your risk. We provide you with stable and high-quality products through a strong quality management process, and the products produced meet the standards of the United States, Canada, the European Union and related industries, making it easier for you to conduct your business in your country or industry.