Insoles are essential products that combine functionality and comfort, catering to diverse demands across various markets. To meet the varied needs of our clients, we offer OEM pre-made product selection and Custom mold development.

Whether you aim to expedite time-to-market with pre-made selections or require mold customization for unique designs, we provide efficient and professional solutions tailored to your requirements.

This guide will introduce the features and suitable scenarios for both modes, along with a detailed analysis of material selection and production processes, empowering you to create high-quality insoles that meet market demands.

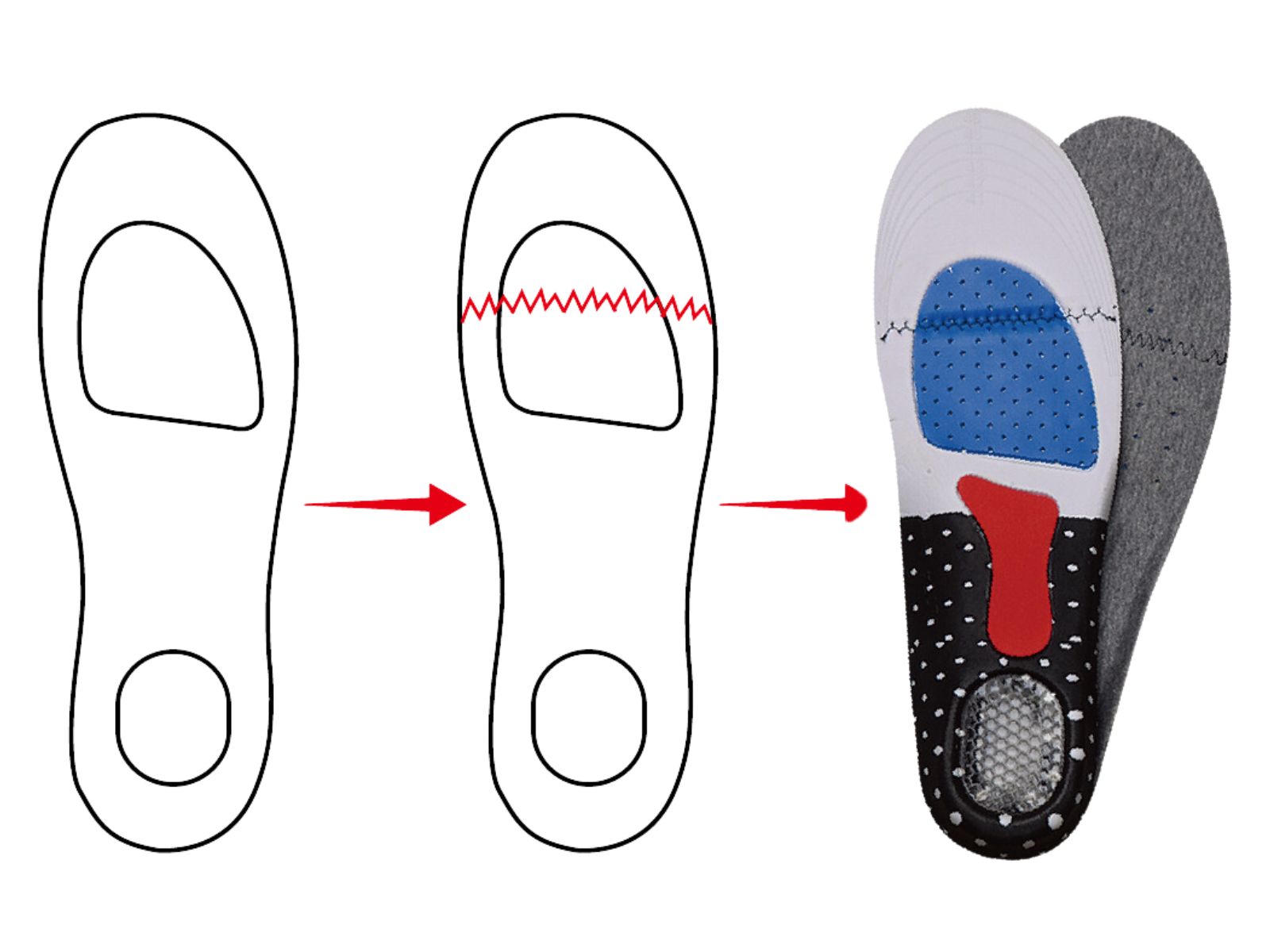

An insole OEM customization, we cater to clients' diverse requirements through two main modes: Pre-made Product Selection (OEM) and Custom Mold Development. Whether you aim for a quick market launch or a fully tailored product, these two modes can accommodate your needs. Below is a detailed comparison of the 2 modes

Features - Utilize our existing insole designs with light customization, such as logo printing, color adjustments, or packaging design.

Deal For - Clients looking to reduce development time and cost while testing the market or launching quickly.

Advantages - No mold development required, short production cycle, and cost-effectiveness for smaller-scale needs.

Features - Fully customized production based on client-provided designs or samples, from mold creation to final manufacturing.

Deal For - Clients with specific functional, material, or aesthetic requirements who aim to create differentiated brand products.

Advantages - Highly unique, designed to meet precise needs, and enhances brand competitiveness in the market.

With these 2 modes, we offer flexible and professional services to meet varying client demands efficiently.

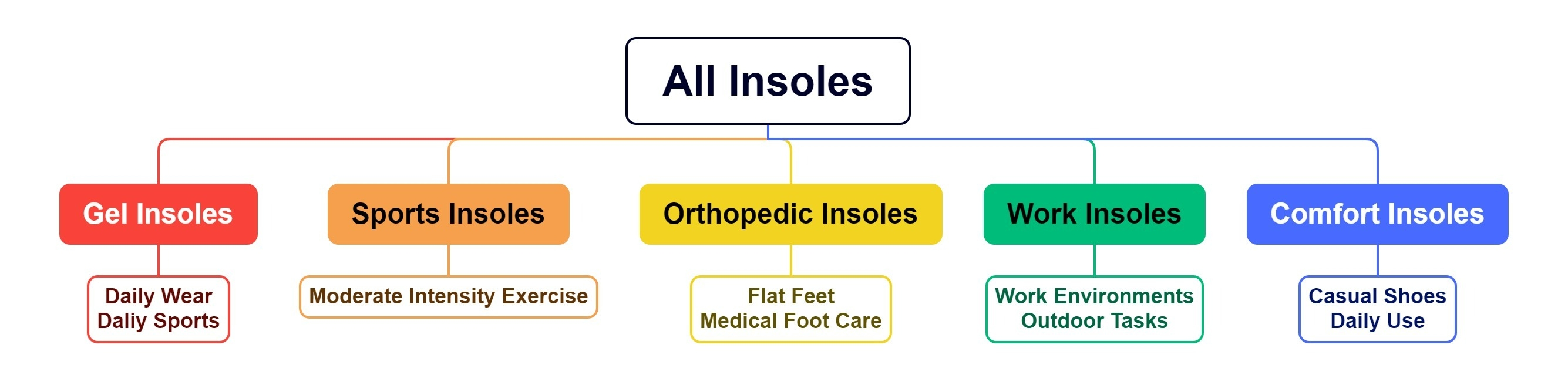

An insole OEM customization, the selection of styles, materials, and packaging is critical to product positioning and market competitiveness. Below is a detailed classification to help clients identify the best solutions.

Based on different use scenarios, insoles are classified into 5 main categories:

Special work insoles please check:

ANTISTATIC INSOLES: The Perfect Pairing with Safety Shoes to Ensure Workplace Safety

Based on functional requirements, we offer four main material options:

| Material | Features | Applications |

|---|---|---|

| EVA | Lightweight, Durable, Provides comfort, Support | Sports, work, orthopedic insoles |

| PU Foam | Soft, Highly elastic, Excellent shock absorption | Orthopedic, comfort, work insoles |

| Gel | Superior cushioning, Cooling, Comfort | Daliy wear insoles |

| Hapoly (Advanced Polymer) | Highly durable, Breathable, Excellent shock absorption | Work, comfort insoles |

We offer 7 various packaging options to meet branding and marketing needs.

| Packaging Type | Advantages | Applications |

|---|---|---|

| Blister Card | Clear display, ideal for premium retail markets | Premium retail |

| Double Blister | Extra protection, ideal for high-value products | High-value products |

| PVC Box | Transparent design, highlights product details | Premium markets |

| Color Box | OEM Customizable design, enhances brand image | Brand promotion |

| Cardboard Wallet | Cost-effective and eco-friendly, ideal for bulk production | Wholesale markets |

| Polybag with Insert Card | Lightweight and affordable, suitable for online sales | E-commerce and wholesale |

| Printed Polybag | OEM logo, ideal for promotional products | Promotional products |

Do you also want to customize your own design of the insoles, from design, material selection, packaging, accessories customization, the logo addition, we can provide you with high-quality service and the nice price.

In insole OEM customization, we also offer a variety of additional services to meet personalized branding requirements:

Insole Pattern Customization

We support the design of insole surface patterns and color schemes based on client requirements.

Case Study: Customizing brand logos and unique design elements to enhance product recognition.

Example: As shown in the image, the branded insole features a unique gradient color design and brand logo.

Display Rack Customization

We design and manufacture exclusive display racks tailored to sales scenarios for showcasing insole products.

Case Study: Display rack dimensions, colors, and logos can be adjusted based on brand needs to suit retail environments.

Example: As illustrated in the image, custom display racks enhance brand visibility and optimize retail space utilization.

Through these additional customization services, we help clients achieve comprehensive support from product development to marketing, creating more opportunities for brand value enhancement.

When collaborating with high-quality clients, we always engage in in-depth communication with a professional industry perspective, helping clients identify market demands and unlock greater business value. Below is a case study involving a major retail client who invited us for an on-site product meeting:

The client was a large international retail chain brand with potential demand for insole products but no specific requirements.

In the absence of clear requirements, we conducted a comprehensive analysis for the client from macro to micro levels:

① Trade Background Analysis

Researched the import-export policies, market trends, and consumer environment in the client's country.

② Market Background Research

Analyzed the key characteristics of the client's market, including market size, growth trends, and primary distribution channels.

③ Consumer Behavior and Demographics

Studied consumer purchasing habits, age demographics, and preferences to guide market positioning.

④ Competitor Analysis

Conducted a detailed competitor analysis in the client’s market, including product features, pricing, and performance.

① Clarifying Client Needs

Based on comprehensive market analysis, we helped the client clarify specific market needs and proposed strategic recommendations.

② Professional Insole Style Recommendations

Recommended the most suitable insole styles and functional categories tailored to the client's market needs and competitor landscape.

③ Thoughtfully Prepared Samples and Materials

Prepared complete samples and detailed PPT materials for the client, covering market analysis, product recommendations, and feasible solutions.

--The client highly appreciated our professional analysis and thorough preparation.

--Through in-depth product discussions, we helped the client finalize their demand positioning and develop a product launch plan.

Through such professional services, we not only provided the client with high-quality product solutions but also enhanced their trust and willingness to collaborate further.

Sample Confirmation, Production, Quality Inspection, and Delivery

At RUNTONG, we ensure a seamless order experience through a well-defined process. From initial inquiry to after-sales support, our team is dedicated to guiding you through each step with transparency and efficiency.

Fast Response

With strong production capabilities and efficient supply chain management, we can quickly respond to customer needs and ensure timely delivery.

Quality Assurance

All products undergo rigorous quality testing to ensure they do not damage the suede.y delivery.

Cargo Transport

6 with over 10 years of partnership, ensures stable and fast delivery, whether FOB or door-to-door.

Start with an in-depth consultation where we understand your market needs and product requirements. Our experts will then recommend customized solutions that align with your business objectives.

Send us your samples, and we’ll quickly create prototypes to match your needs. The process typically takes 5-15 days.

Upon your approval of the samples, we move forward with the order confirmation and deposit payment, preparing everything needed for production.

After production, we conduct a final inspection and prepare a detailed report for your review. Once approved, we arrange for prompt shipment within 2 days.

Receive your products with peace of mind, knowing that our after-sales team is always ready to assist with any post-delivery inquiries or support you may need.

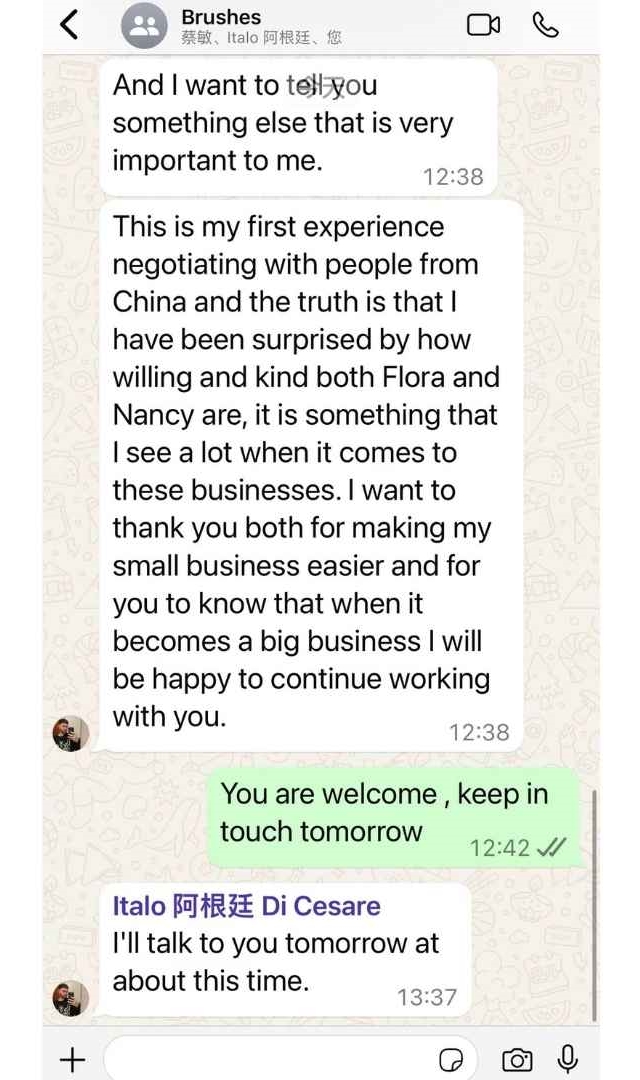

Our clients’ satisfaction speaks volumes about our dedication and expertise. We are proud to share some of their success stories, where they have expressed their appreciation for our services.

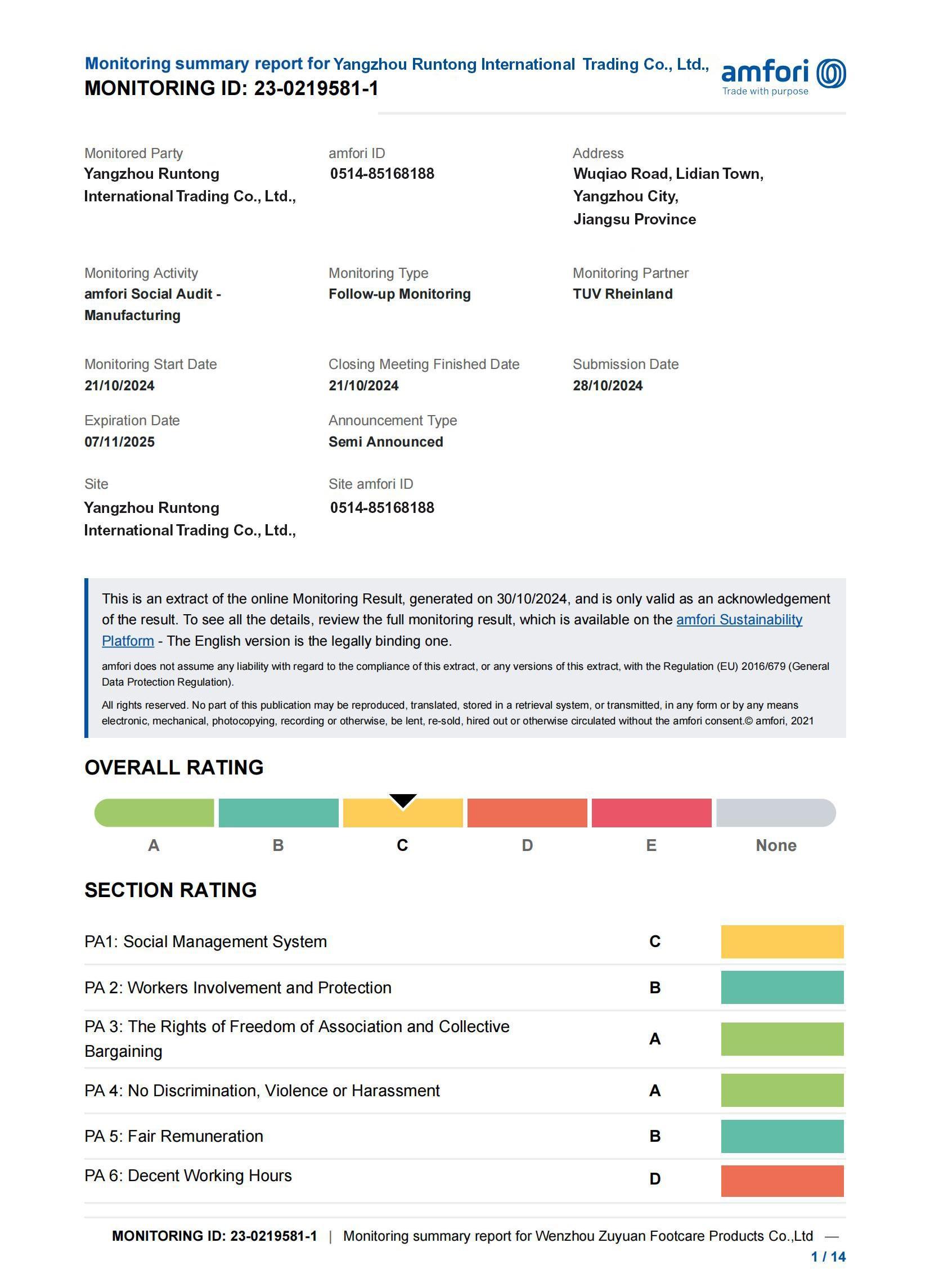

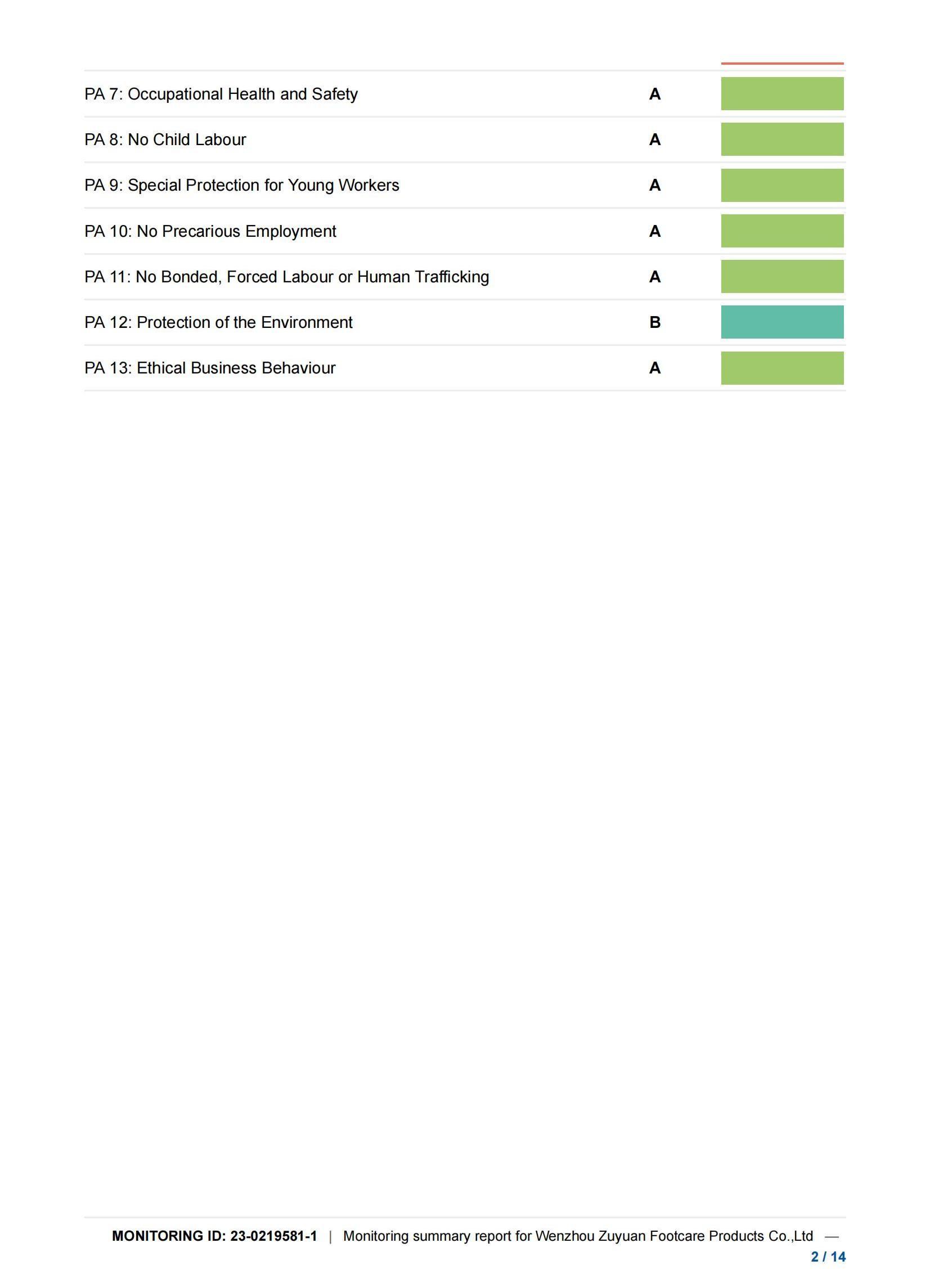

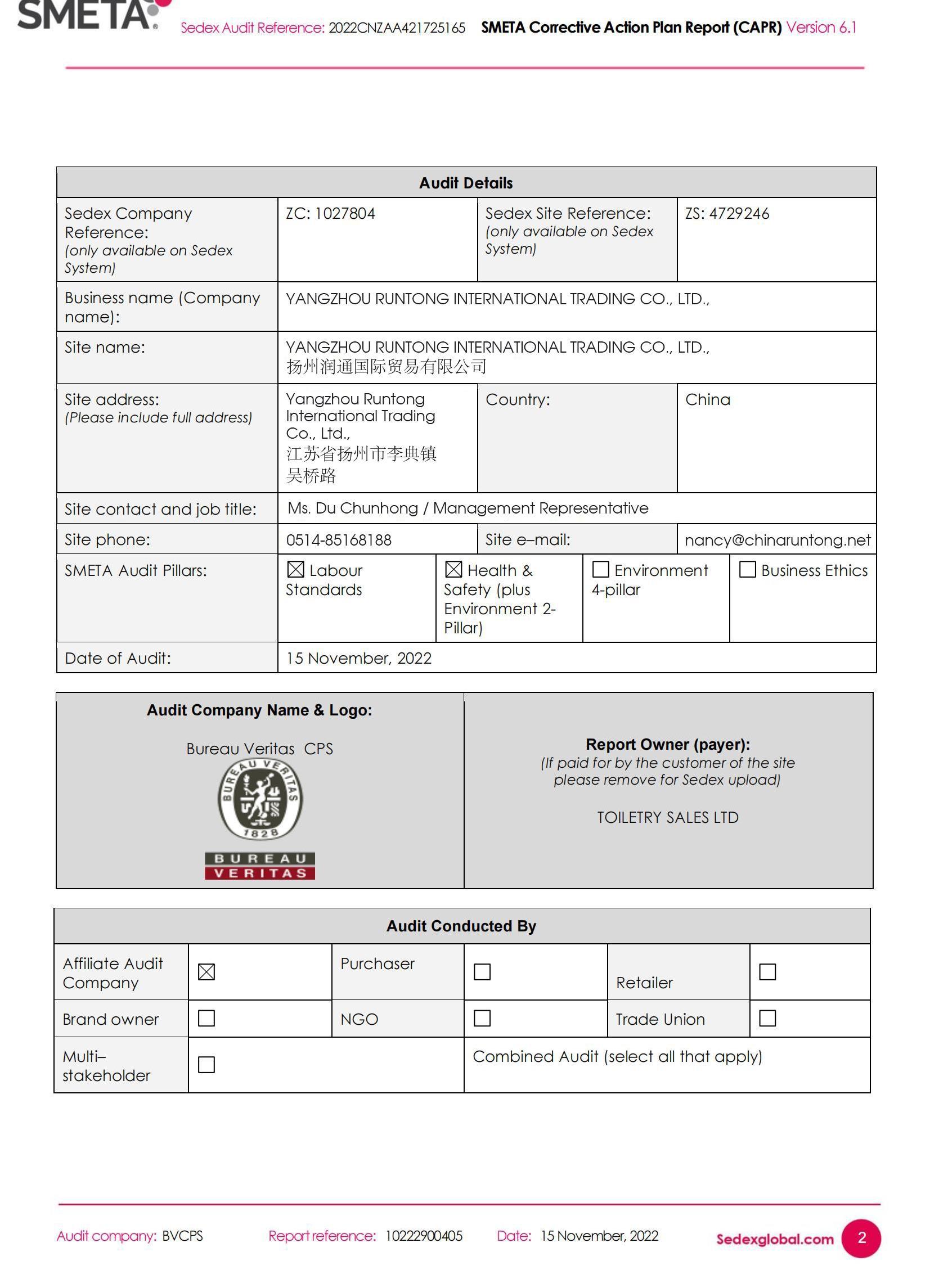

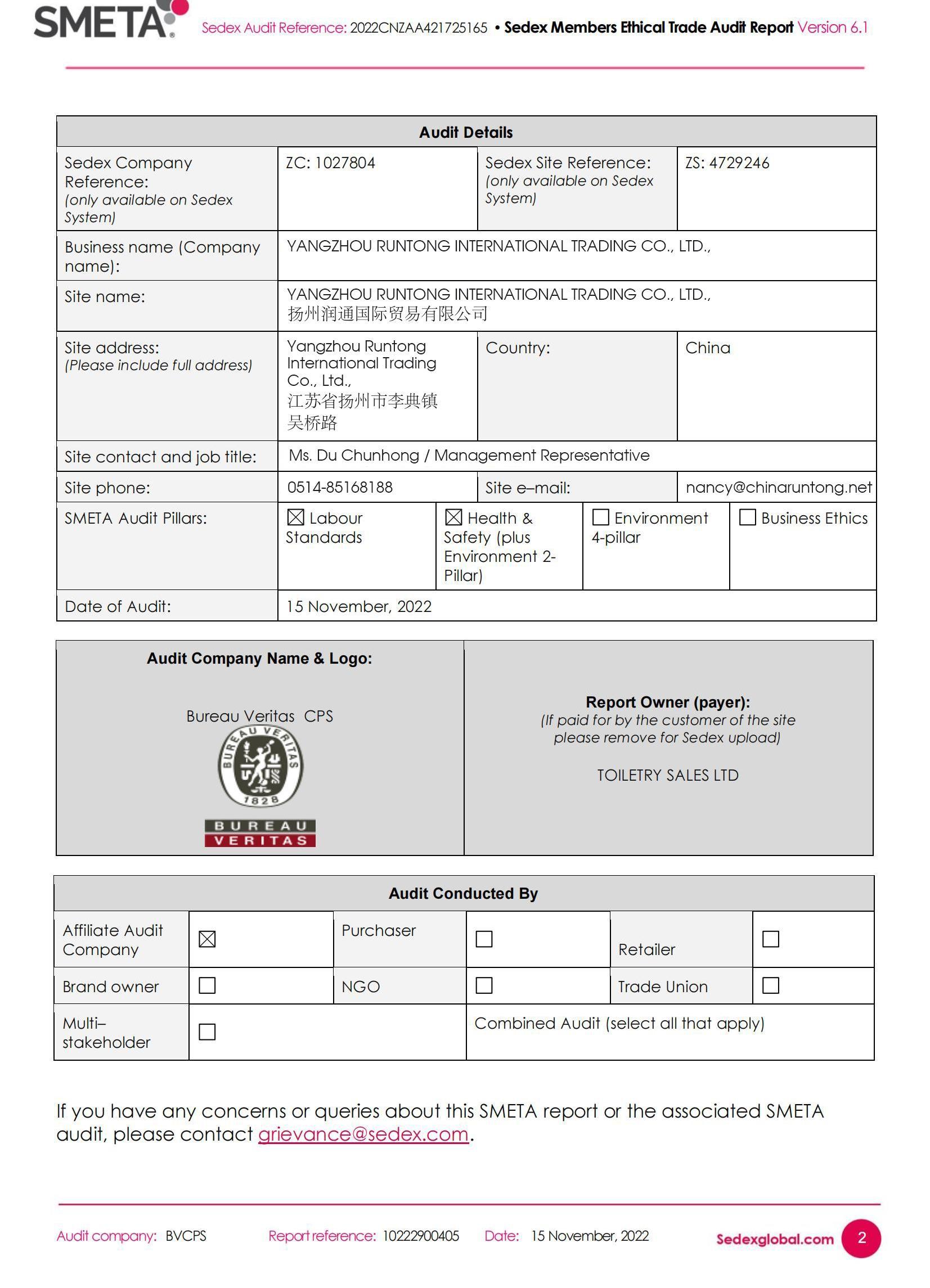

Our products are certified to meet international standards, including ISO 9001, FDA, BSCI, MSDS, SGS product testing, and CE certifications. We conduct rigorous quality control at every stage to guarantee that you receive products that meet your exact specifications.

Our factory has passed strict factory inspection certification, and we have been pursuing the use of environmentally friendly materials, and environmental friendliness is our pursuit. We have always paid attention to the safety of our products, complying with relevant safety standards and reducing your risk. We provide you with stable and high-quality products through a strong quality management process, and the products produced meet the standards of the United States, Canada, the European Union and related industries, making it easier for you to conduct your business in your country or industry.